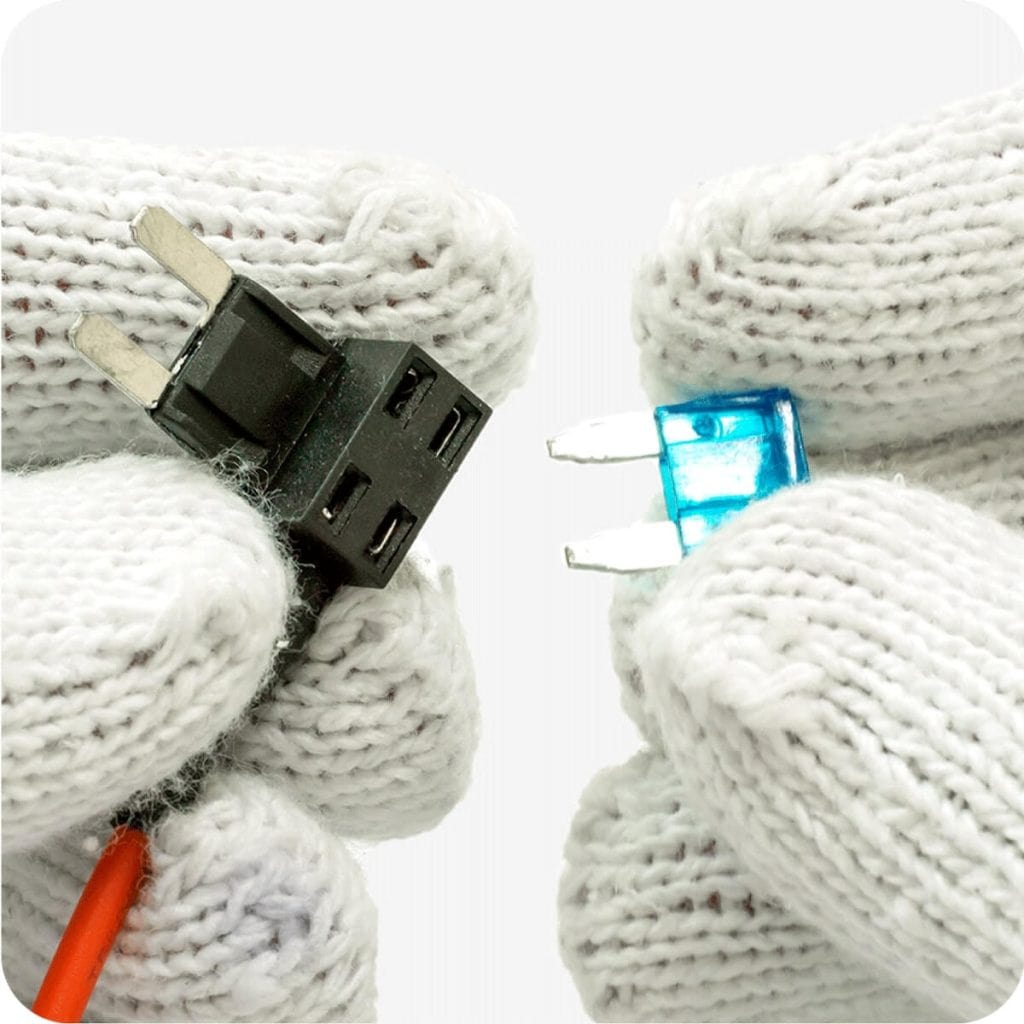

Fuses

Many styles of innovative, versatile fuses are available to protect circuits from dangerous overcurrents in automotive, electronic, and industrial applications.

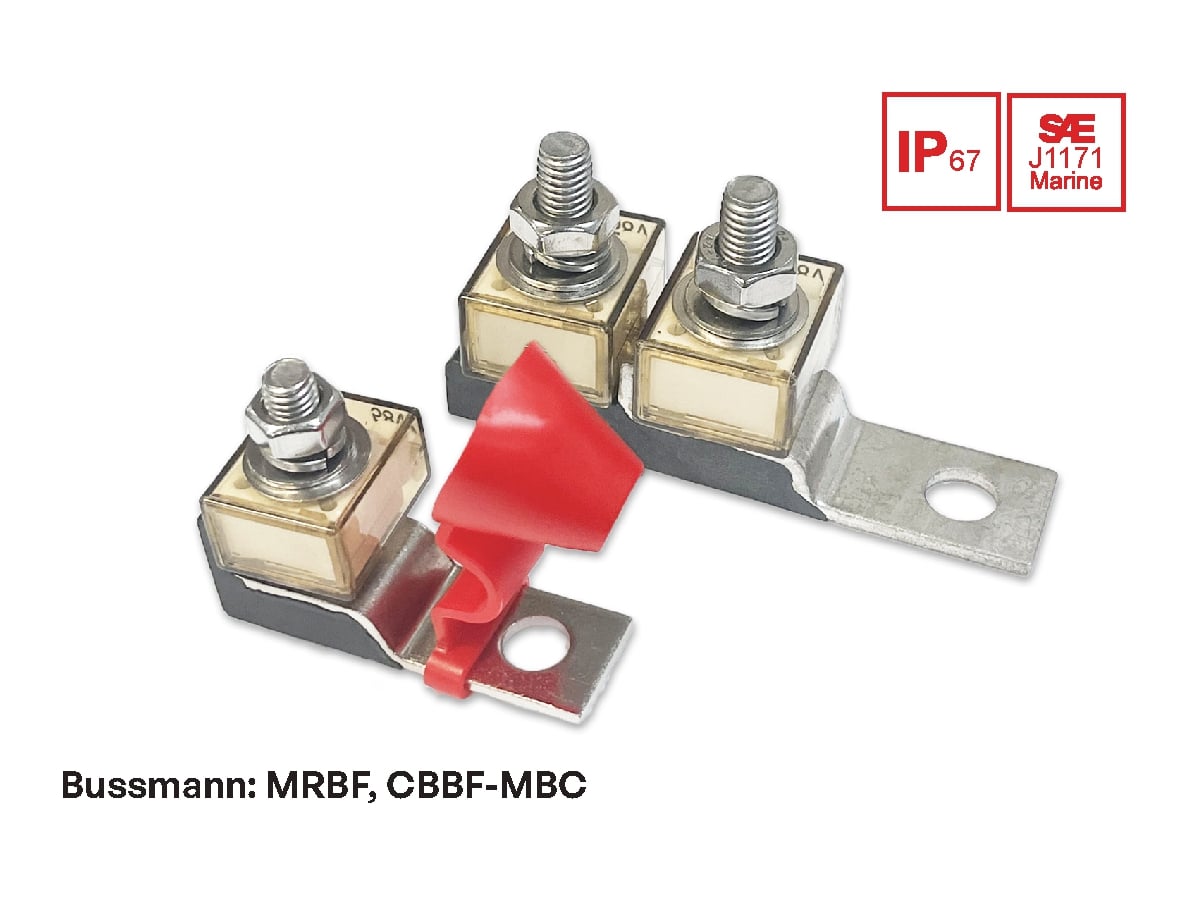

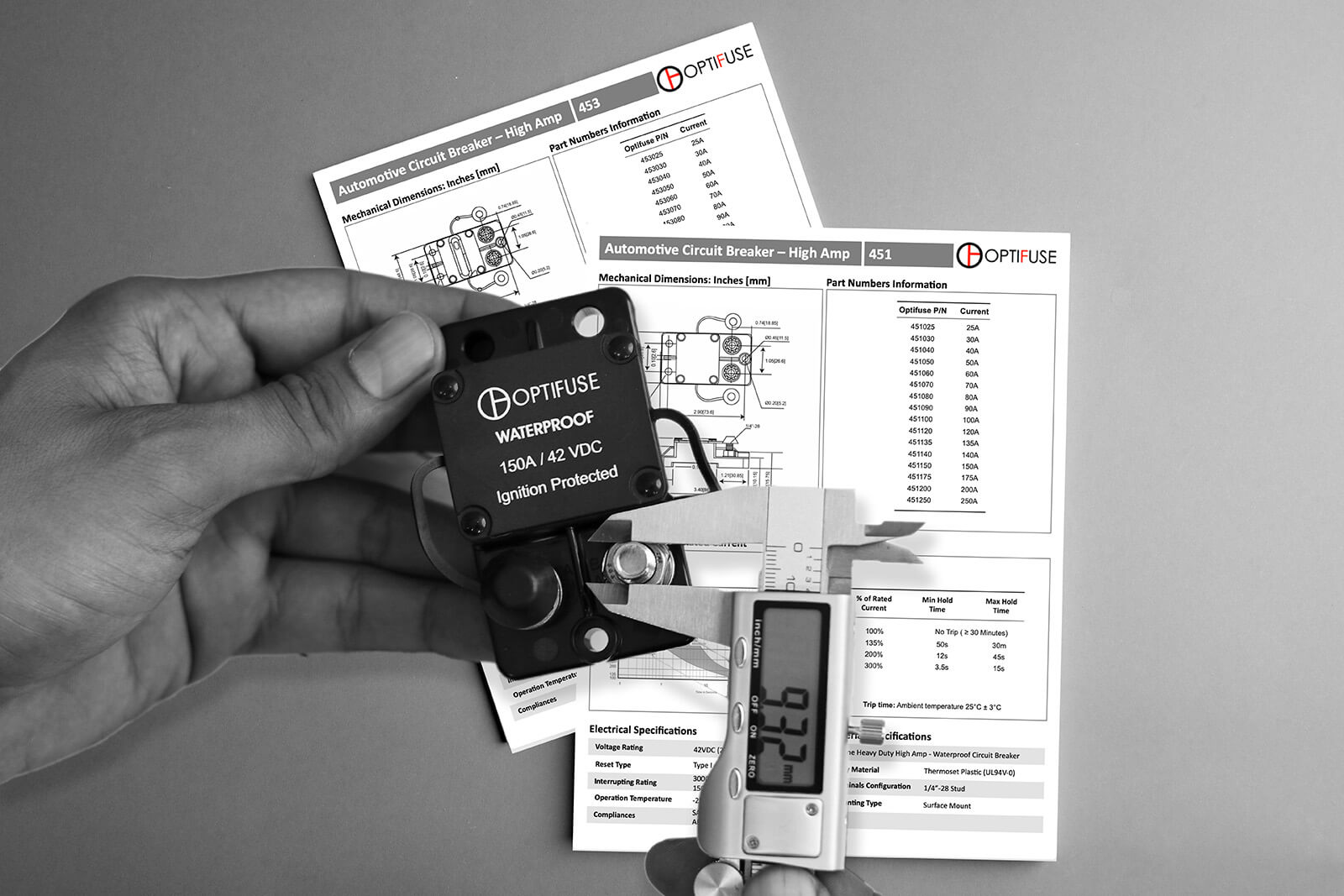

Circuit Breakers

A comprehensive range of automotive, marine grade and line voltage circuit breakers to protect applications where resettability is needed.

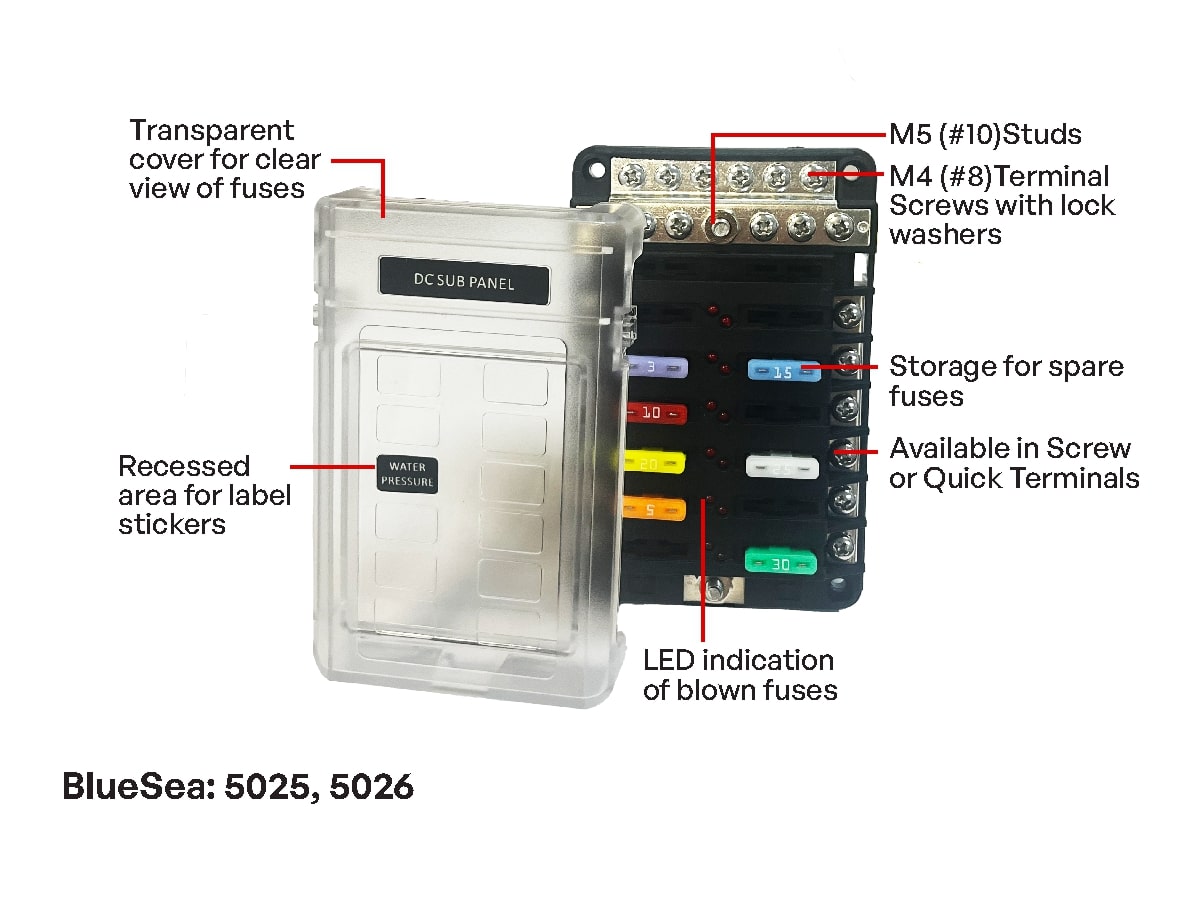

Fuse Holders, Blocks and Accessories

Installing circuit protection is easy with our wide variety of customizable fuse holders, sturdy fuse blocks, and compact fuse clips.

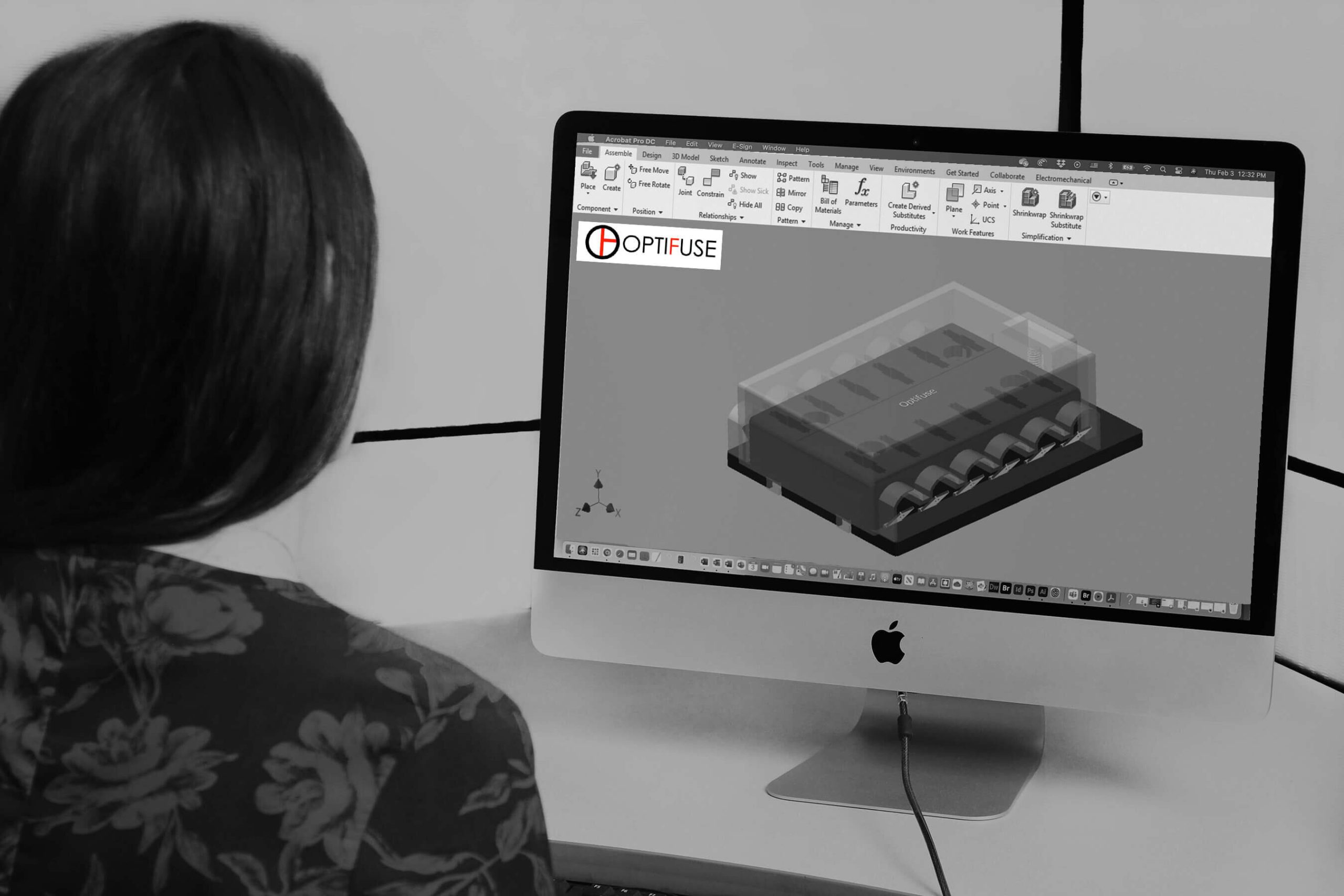

New Products

Discover the latest in circuit protection at OptiFuse. Let our expertise be at your service.

About Us

Distributor focused and growth minded. We are always striving at getting better at helping you succeed.

Find a distributor

OptiFuse