RV Fuses Explained: How to Protect Your Camper’s 12VDC Electrical System

If you’re new to sizing and applying fuses, start with our Fuse Selection Guide. In just a few minutes, it walks you through the core principles you’ll see throughout this article.

A fuse is your last line of defense against burnt wiring, damaged gear, and fires. In RVs, where 12 VDC and 120 V AC often live side-by-side, matching the right fuse type and location keeps faults from turning into costly disasters. In some locations, resettable high-amp circuit breakers are used instead of fuses, but they follow the same basic rules: protect the wire, clear faults quickly, and keep energy contained.

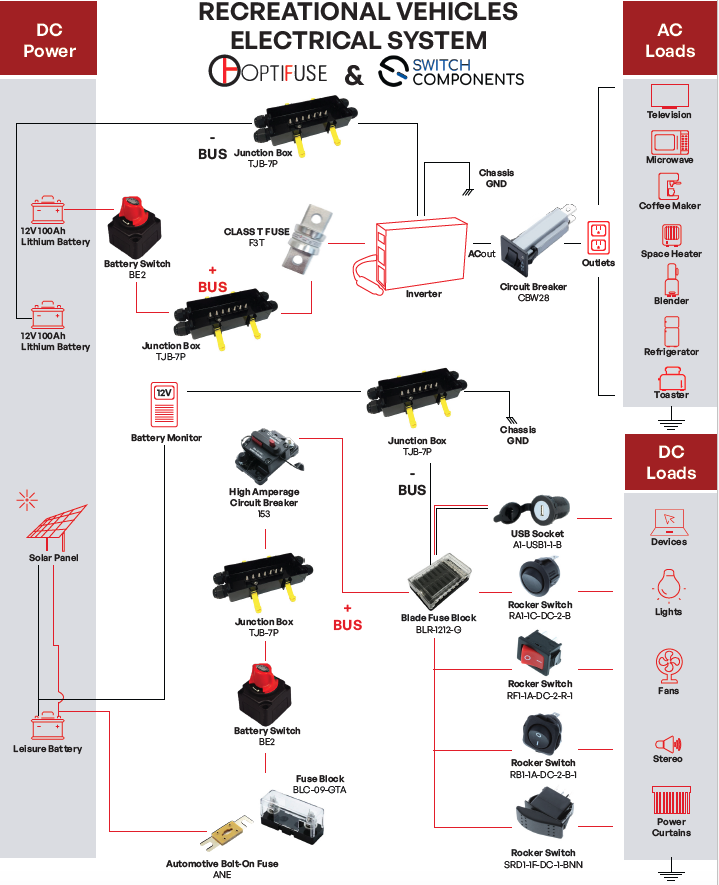

RVs pack a lot of electrical gear into a small, mobile space: batteries, inverters, solar, slide motors, fans, pumps, and all the creature comforts of a tiny home on wheels. Long, unoptimized wire runs, vibration, and DIY add-ons all increase the chances of a short-circuit or overload—making proper fuse protection essential for preventing damage and ensuring system safety.

Explore our OptiFuse for Recreational Vehicles catalog to find fuses and circuit breakers designed for reliable, durable protection in every RV system.

In this article, we’ll focus on 12V DC fusing—the components that protect your batteries and 12V distribution.

120 V AC side (Shore/Generator)

Typically breaker-protected

- Shore power inlet

- Generator output

- Inverter AC output

- Receptacles/outlets

- Microwaves, televisions, and other AC appliances

12 V DC side (House System)

- Battery banks (lead-acid, AGM, lithium)

- Interior and exterior lights

- Water pump and fans

- Refrigerator electronics and control boards

- Solar charge controllers and DC-DC chargers

- Inverter DC inputs and other add-on accessories

1. Common RV Fuse Types (What to use, and where)

Blade fuses [1A-80A]

Blade fuses are the most common fuse found in RVs. They’re popular because they’re compact, inexpensive, and easy to diagnose at a glance. If the link is melted, you see it within seconds.

- Use blade fuses for low to mid-current RV circuits: lights, fans, USB/aux ports, control circuits, and small pumps.

- Pair them with covered blade fuse blocks so labels stay tidy and roadside diagnostics are quick.

- OptiFuse has all sizes available:

- MICRO 3 Style | MICRO2 Style

- Mini Style | Mini Style – Low Profile

- Regular (ATO/ATC Style)

- Maxi Style

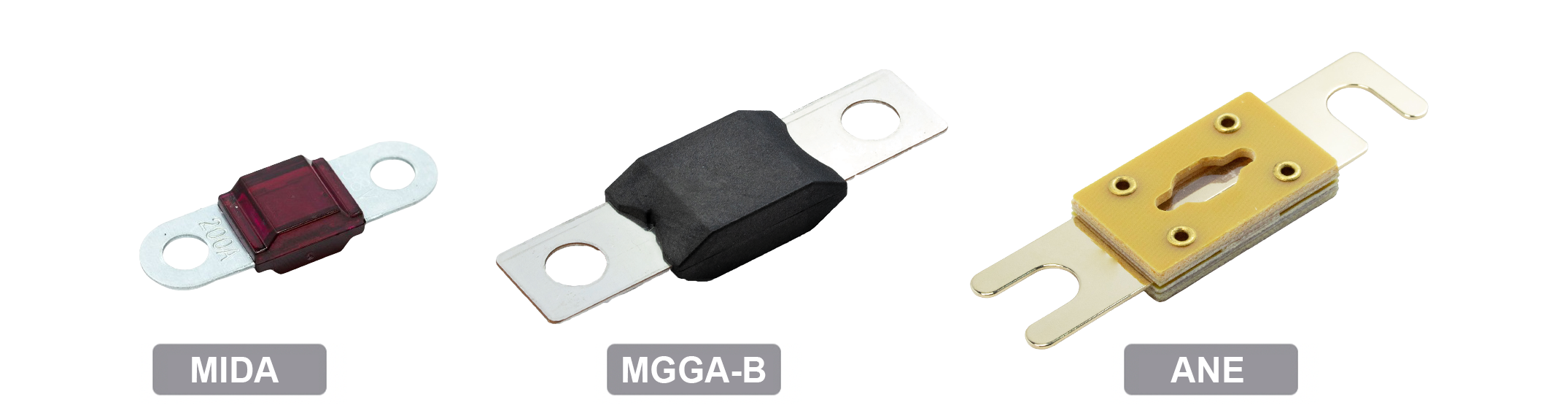

Bolt-On Fuses for High-Current RV Circuits

~30-200 A

Small/mid inverters, DC-DC chargers, sub-panels

Compact, good for medium feeders close to the source

~100-300 A

Larger inverters, big DC-DC chargers, alternator feeds

Widely used in van/RV upfits, broad rating range

~35-400A

Main battery feeds, alternator charge lines, inverter inputs

Clear window that allows for easy open fuse identification

- Use MIDI-style fuses for medium-current feeders, like small/mid inverters, DC-DC chargers, and distribution sub-panels.

- OptiFuse MID/MIDA fuses are compact, vibration-resistant, and mount close to the source to minimize unprotected cable.

- Pair with MIDI fuse holders / covered blocks for safer, serviceable installs.

- Use MEGA-style fuses for ~100–300 A higher-draw devices: larger DC-DC chargers, mid/large inverters, and high-output alternator feeds.

- They’re popular in RV and van upfits due to their broad current range and rugged terminations.

- OptiFuse’s MGGA-B cover common MEGA-style ratings.

- Use ANL-style fuses for ~35–400 A main battery feeds, alternator charge lines, and inverter inputs.

- OptiFuse’s ANE and ANF provide ANL-style performance with compatible blocks and limiter options.

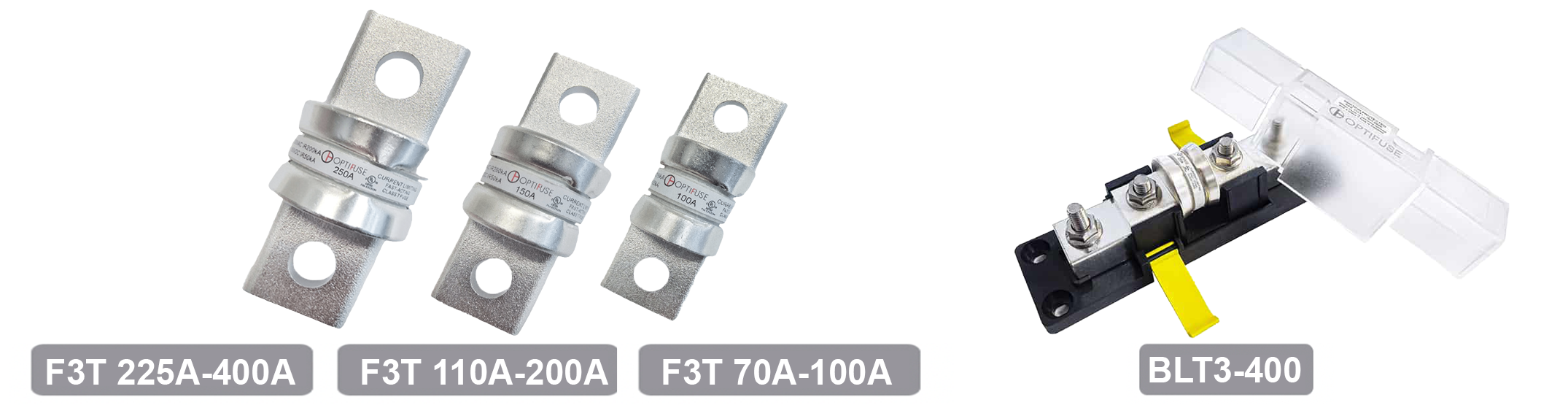

UL Listed, Class T Fuses

Class T fuses range from 1 to 1200 A at 300 VAC / 160 VDC and are very fast-acting with a high interrupt rating, making them ideal for applications where battery banks and inverters can deliver huge fault currents. With silver-plated blades for corrosion resistance and fast short-circuit response, OptiFuse’s Class T Fuses are excellent candidates for inverter and battery protection in demanding RV systems. See F3T Class T fuses for more detail.

To mount these fuses in an RV, OptiFuse offers Class T fuse blocks designed around real-world marine/rv installs:

BLT3-200 mounts 110A-200A fuses

BLT3-400 mounts 225A-400A fuses

When paired with an F3T fuse, both blocks are ignition-protected and include an insulating cover that meets ABYC requirements. Each features a four-stud layout, making it easy to connect batteries, inverters, and bus bars without fighting for space.

High-Amp Circuit Breakers (When a Resettable Device Makes Sense)

In the same current ranges as MIDI/MEGA/ANL fuses, many RV builders use high-amp circuit breakers for certain loads:

- Typical range: roughly 25-300A, depending on breaker style

- Common RV uses slide-out motors, leveling jacks, tongue jacks, winches

Why choose a breaker instead of a fuse?

- Automatic reset, modified reset, manual reset capabilities available

- Can double as a local disconnect in a pinch

- Easy to troubleshoot in the field

See OptiFuse’s high-amp circuit breakers page for more information.

Key things to watch:

- DC voltage rating: Make sure the breaker’s DC rating meets or exceeds your system voltage (12/24/48VDC), not just the AC rating on the label.

- Interrupt rating (AIC): Just like fuses, high-amp breakers must be able to safely interrupt worst-case fault current that can be seen by the breaker

- Continuous rating: Many thermal breakers can run warm at their respective rating. Treat their “30 A” or “100 A” rating like a continuous rating and size wiring and loads accordingly.

- Environment and mounting: Stud-type and panel-mount breakers need secure mounting and strain-relieved cables; vibration and heat can impact long-term performance.

This article focuses on fuses first, since they set the baseline for overcurrent protection. In many well-designed RV systems, you’ll see a mix of bolt-on fuses for main battery / inverter feeds and high-amp breakers where reset capability and visual status are helpful.

2. How to Size an RV Fuse

1. Start with the wire

Choose a fuse rating at or below the wire’s ampacity. The fuse’s primary job is to protect the conductor, then the equipment.

2. Account for continuous load

For loads running 3+ hours (fans, fridges), target ~125% of continuous current so nuisance openings are minimized.

3. Check voltage & interrupting rating (AIC)

DC arcs are stubborn, especially with big lithium banks or large inverters. Verify the fuse has a DC voltage rating that meets or exceeds system voltage and a sufficient interrupt rating for worst-case fault current.

4. Choose form factor & holder type

Match the environment: vibration (bolt-on), serviceability

Match the mechanical environment:

- High vibration, high current: bolt on fuses and stud-type breakers or blocks

- Serviceable low currents: blade fuses in organized fuse blocks

3. Placement That Actually Protects

Fuse every positive conductor leaving the battery bank

Main feed, inverter feed, DC-DC charger feed, solar/controller feed, each should have its own fuse or breaker mounted as close to the battery as practical.

Keep unprotected lengths short

Aim to minimize the length of the cable between the battery and the first overcurrent device. Where you can’t, add abrasion protection, loom, or conduit in tight runs under floors, through walls, or near metal edges.

Fuse sub-panels and branch circuits appropriately

Main DC fuse -> sub panel -> properly sized branch fuses for each load. This keeps fault energy localized and simplifies troubleshooting.

4. Selecting the Appropriate Fuse Holder

Once you’ve chosen a fuse, match it with a holder suited to the location, environment, and service needs:

In-line fuse holders:

- Small form-factor, great for single-circuit branch protection near the load or source

- Ideal for add-on accessories, 24-hour “always-hot” circuits, and simple retrofits

- See OptiFuse’s LPR-02, LPM-08, LPX-02

Fuse blocks/panel-mount:

- Allow for centralized distribution, easier labeling and troubleshooting

- Options for clear insulating covers, LED blown-fuse indication, split buses, and ground buses

- See our BLR-I-504, BLC-106-G, BLR-I-1212-G

Sebastian Castañeda is a circuit protection specialist and technical writer with application-focused experience in technical support and custom protection design. He contributes practical, application-driven insights to the OptiFuse Blog.