Available Fault Current (AFC): What It Is, Why It Matters, and How to Apply It

Available Fault Current (AFC), often called prospective short-circuit current, is one of the most important numbers in power distribution and industrial electrical design.

If you design, build, install or maintain electrical equipment (switchboards, panelboards, industrial control panels, machinery, HVAC equipment, battery/inverter systems, etc.), AFC is a baseline value you must know at the point of installation. It directly impacts:

- Protective device selection (fuse / breaker interrupting rating)

- Equipment ratings (SCCR, withstand capability)

- Code compliance and inspection readiness

- Safety (fault containment, arc-flash risk reduction)

AFC is the maximum current that could flow during a short-circuit at a specific location in the system, typically evaluated at the line terminals of equipment.

What Determines Available Fault Current

AFC isn’t a single “building value.” It changes from point to point as you move through the electrical system because impedance (resistance + reactance) increases as you go downstream.

When engineers estimate or calculate AFC, they typically account for:

1. Utility / source strength

The upstream supply capability (utility transformer size, service capacity, and available fault contribution.

2. Transformers

kVA rating and % impedance (%Z) are major drivers of how much fault current is available on the secondary.

3. Conductors and bus

Feeder length, conductor size/material, and routing all add impedance and reduce available fault current downstream

4. Motors and generators (fault contribution)

Rotating equipment can contribute additional short-circuit current, especially for “close-in” faults near motor control centers

The closer you are to the source (utility/transformer), the higher the AFC tends to be.

The farther downstream you go (longer runs, smaller conductors), the more AFC typicall.

Why AFC Matters for Safety

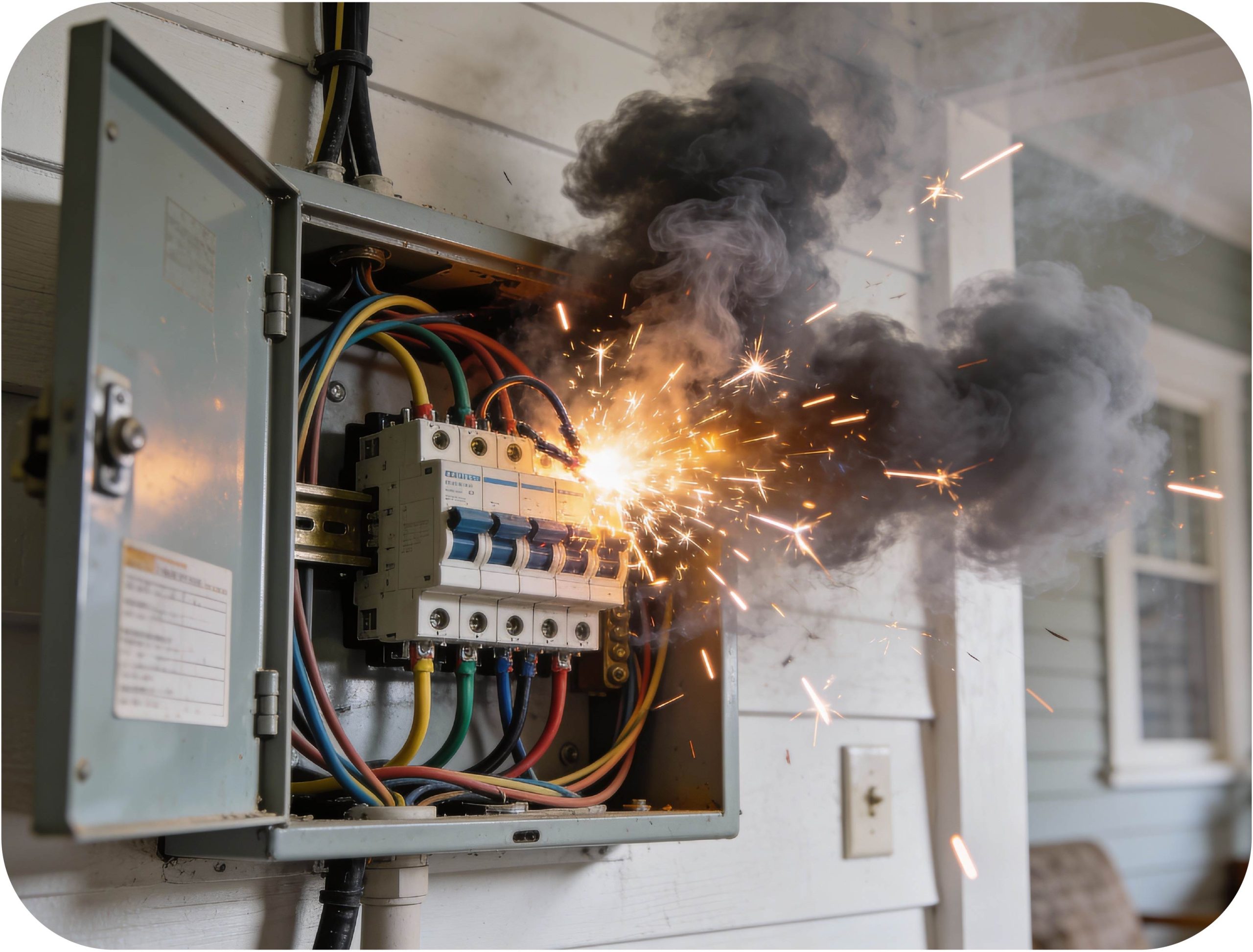

During a bolted fault, current rises extremely fast. If your overcurrent protective device (OCPD) can’t safely interrupt the available fault current, the result can be catastrophic: ruptured devices, equipment damage, arc-flash escalation, fire, and serious injury.

Key Terms and Definitions

- Available Fault Current (AFC): The prospective short-circuit current available at a specific point (often at the line terminals of equipment).

- Interrupting Rating (IR) / AIC (Amperes Interrupting Capacity): For fuses and circuit breakers, the maximum fault current the device can safely interrupt at its rated voltage.

- SCCR (Short-Circuit Current Rating): For equipment/assemblies (like industrial control panels), the maximum fault current the equipment can withstand under defined conditions without unacceptable damage. Please see our Introduction to SCCR article for more information.

- Current-Limiting Protection: A fuse (and some protective devices) that reduces let-through energy: both peak current and I²t, helping downstream components survive a fault.

The Rule of Thumb

At the point of installation, you’re always checking the same relationship:

Protective device interrupting rating must be ≥ AFC

OCPD AIC/IR ≥ Available Fault Current (AFC)

Equipment SCCR must be ≥ AFC at its line terminals (as applied)

Equipment SCCR ≥ Available Fault Current (AFC)

If either of those is not true, the installation is at risk and often non-compliant.

How to Get AFC for a Site

Common ways AFC is established:

- Utility-provided available fault current at the service point (often available by request)

- Short-circuit study (engineering calculation using system data)

- Onsite field verification of configuration + nameplate data (then calculation)

For industrial sites, the most reliable path is usually a short-circuit study that reflects actual operating modes (normal, generator, tie closed, etc.).

When AFC Is High, Focus on Let-Through Energy

Sometimes the available fault current at a facility is simply high (large service, close to a transformer, low-impedance feeders). In those cases, the most practical way to protect lower-rated downstream components is current-limiting protection. Reducing peak let through and I²t that downstream devices experience during a fault.

A classic SCCR “save” is upgrading feeder protection from a less current-limiting option to a current-limiting Class J T6J fuse so downstream components see dramatically less let-through energy during the fault event.

Where OptiFuse industrial fuses fit:

Branch Circuits with inrush (control transformers, solenoids, small motors):

Class CC time delay (TPK-R) helps ride through startup surge while still providing current-limiting short-circuit protection.

Higher-performance feeder:

Class J (e.g OptiFuse T6J) is commonly used when you need strong current-limiting behavior to help downstream components stay within their SCCR during a high-AFC fault.

Need a quick refresher on fuse clases (CC, J, T, RK5) and where they’re used: See our Industrial Fuses article to learn more about the types of protection classes. See our Fuse Selection Guide for complete context.

Sebastian Castañeda is a circuit protection specialist and technical writer with application-focused experience in technical support and custom protection design. He contributes practical, application-driven insights to the OptiFuse Blog.